|

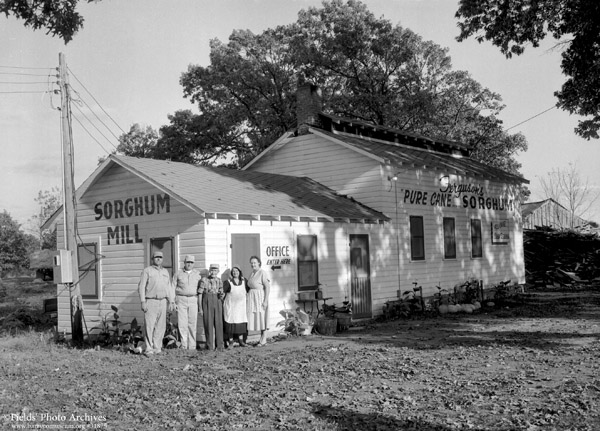

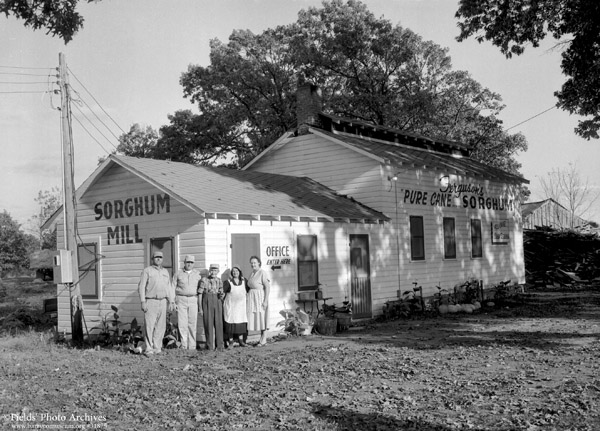

Furguson Sorghum Mill in 1959 |

Sorghum Syrup (Molasses) made the Hankins-Ferguson Way by Carl Ferguson |

Sorghum cane processed by the Hankins/Ferguson Mill in Butterfield, for the most part, was grown by farmers in Butterfield and the surrounding communities. Dad usually planted about four or five acres, and Hankins, less or none at all. The company, the name Golden, and Dad used to refer to their partnership, kept either 2/5ths of the custom made sorghum as their charge, or a farmer could pay the equivalent in cash. When sorghum sold for one dollar per gallon, the usual price for many years during the 1920’s and early 1930’s, the charge for making the sorghum would be a straight 40 cents a gallon.

If the cane grower did not have seed, the company would, if requested, furnish seed of one of the favorite varieties of that period; Sea island, silver drip or ribbon cane. The usual planting rate varied, but if planted by hand in a well-prepared seed bed, one gallon of seed would plant two acres. |

Soils and Sorghum Cane |

Sorghum cane can be grown successfully on a wide variety of Ozark soils. With the use of a moderate amount of chemical fertilizers containing available nitrogen, phosphorus, and potassium even the less fertile soils are capable of producing cane which will make light amber-colored mild-flavored/sorghum. Dad always advised against application of large amounts of barnyard manure on land to be planted in sorghum cane. He had observed that such land invariably produced a syrup that was dark in color and very strongly flavored. |

|

Henbest Cane 1955 |

Harvesting the Cane |

In the Fall (September and October) when most of the seed heads had matured and the stalks had taken on a yellowish green color, it was time to harvest the cane. The juice or sap of the cane had reached its highest sugar content. The first step was to cut off the seed heads using a machete (corn knife). Normally, several inches of the upper part of the stalk would be removed with the seed head. Most of the leave would still be green and easily removed by hand with a wooden paddle 24 to 36 inches in length. Unstripped cane would never have been processed by the Hankins/Fergusons, or later by the Ferguson Mill. The next step, cutting and piling the cane ready for transport, required a sharp machete in the hands of a person skilled in its use. One had to cut the stalks near the ground but avoid getting soil on the cut butt ends.

The neatly stacked piles of cane were transported as soon as possible to the mill, usually by horse-drawn wagon, flat bed or pickup truck. Early delivery to the mill reduced the loss of moisture from the cane by evaporation, and assured earlier processing by the mill. It was important that the cane be free of dirt, mud, cane leaves, seed heads or other trash.

At the mill, the manager of the cane yard assigned a place for the cane to be stacked in a neat pile with butts aligned and stalks parallel. He would post a ticket alongside the stack bearing the name of the owner, and the number indicating his place in the order for processing. |

|

Henbest Sorghum Mill, Roger Henbest and Jimmy Lewis |

Crushing the Cane |

Although it has been more than sixty years since I helped make sorghum in Butterfield, my memory of the basic operations is still quite clear. Sorghum making by Hankins/Ferguson moved in 1921 from the Hankins farm located one mile south of Butterfield to the town lots across the street from the Ferguson home. The mill was powered by two horses hitched to a long sweep connected to upright steel rollers. For several years during the 1920’s and possibly in 1930, Elmer Savage (son of Dave Savage) and Noel Lewis (son of Dave Lewis) handled the crushing part of the sorghum making operation.

Noel carried fresh cane from stacks in the yard to the mill and removed the crushed stalks (pummies or bagasse) which accumulated behind the mill. The juice ran into a half-barrel container connected to the evaporator by a one inch pipe.

This mill could produce only enough juice to meet the requirements of a ten foot evaporator. The evaporator rested on a stone and concrete furnace fired with dry oak wood. Forty to fifty gallons per day was the usual output.

The Gasoline Powered Mill and Installation of an Electric Motor

About 1930, the Company bought a 6-hp Fairbanks-Morris one cylinder stationary gasoline engine to power a new mill with horizontal rollers. The output of this larger mill, was enough to meet the capacity of a 12 foot evaporator. This improved mill enabled the sorghum maker to turn out up to 100 gallons of the syrup in a long day. Several years later, a larger mill powered by a large electric motor, was installed, providing juice for a 15-foot evaporator. Production of sorghum reached its peak after installation of these larger facilities. |

|

Henbest Sorghum Cooking 1955 |

Cooking the Juice |

The filtered juice ran by gravity flow from a large galvanized tank into the “cool” end of the evaporator. A faucet regulated the amount and timing of the flow. The sorghum maker had two major concerns; an adequate supply of fresh juice, and control of the fire in the furnace. His goal was to have raw juice coming into the front end of the evaporator and finished sorghum being almost constantly drawn off into the cooling vat from the upper end.

Approximately eight gallons of juice had to have seven gallons of water boiled away to produce one gallon of syrup. This required constant heavy boiling over a hot fire. By comparison, to make maple syrup requires boiling away from 30 to 40 gallons of water for each gallon of syrup. Operation of the furnace required the full-time attention of two persons. The sorghum maker was responsible for the final cooking on the upper end of the evaporator, and the drawing off of the finished product into the cooling vat in the attached molasses house.

The second person regulated the flow of the green juice into the evaporator, removed the green skimming which formed on the surface of the heated juice, and controlled the fire by adding wood and removing wood ashes as needed. The skimming contained edible plant materials (chlorophyll, sugar and starches). They were collected and fed to the pigs and other livestock.

Neither Golden nor Dad used a thermometer to determine when the sorghum was “ready” to be drawn off. They relied entirely on visual observation of the boiling syrup, noting the color, how it dripped from the stirring paddle and feel of the paddle as it was drawn through the boiling syrup. Constant stirring with the paddle during the last stages was required to prevent sticking to the bottom of the pan and scorching of the syrup.

The Hankins/Ferguson method of sorghum manufacture differed from the techniques employed by some of the larger molasses factories. Nothing was added to the juice either before or during the cooking process. No chemicals or other additives were added for clarification of the juice before cooking, or for prevention of crystallization of sugars in the finished product, and no preservatives to extend shelf life. |

|

Henbest Sorghum 1955 |

Measuring and Division of the Sorghum |

The finished syrup ran directly into a cooling vat in the adjoining molasses house. Until Dad took over the sorghum maker’s job when Golden Hankins retired in 1944, he was responsible for measuring and dividing the sorghum between the cane owner and the company, three fifths to the owner and two fifths to the company. Only a few farmers paid cash for the making.

Most of the Company’s share was poured from a graduated one gallon measure into new, gallon size, metal buckets with a smaller amount going into one-half gallon buckets. The owners share was poured into containers of which one might see an interesting collection of lard cans, cream cans and metal buckets of varying sizes. Wooden containers included small kegs, small barrel and medium size barrels. Ceramic jugs were a favorite of some of the old timers. The wooden barrels were the least reliable. Although molasses flow slowly, it can seep through the smallest opening, and that happened occasionally.

In 1944, Golden Hankins retired from sorghum making and Dad took up the sorghum making business having started in 1915, two years after he and my mother were married. When dad began spending full time at the “business end” of the evaporator, my mother, Flora, measured the sorghum and made the division between cane owner and the company. She also handled sales to customers who stopped at the mill during working hours. |

Marketing the Sorghum |

Many regular customers would stop by, or even make a special trip to buy Hankins/Ferguson sorghum. It was not unusual for tourists to include a visit to the Butterfield sorghum factory on their itinerary. The Company did no traditional advertising, relying on customers and tourist visitors. However, in years of very heavy production when the mill ran around the clock for some weeks, there was some transport of sorghum to urban areas. |

|

Homer Henbest Cane |

Amount of Sorghum Made |

Production varied widely due to the variability of growing conditions. Sorghum cane, a member of the grass family, naturally responds markedly to rainfall amounts and distribution. Even a short drought at a critical time can affect the volume of cane produced. An extended drought such as that of 1954 can devastate the crop. In that year, production was less than 1000 gallons. The year of greatest production was 1942 when production of the prized sweetener exceeded 8000 gallons. In 1955, a good year for cane in Barry County, the Ferguson Mill made about 4000 gallons.

Use of the Crushed Cane Residue--Pummies

The crushed cane residue served an important role in the strawberry industry which flourished in the Butterfield community during the sorghum making era. The pummies made an excellent mulch on strawberries to protect against severe freezes and covering the bare soil under the plants. The result was clean dirt-free berries. |